Remarks: 1) Price Term: FOB NINGBO 2) Payment: T/T (30% for deposit, 70% before delivery) 3) Load time: 30 working days at sight the deposit. 4) After sale service: Spare parts guarantee for one year in machine arrival.

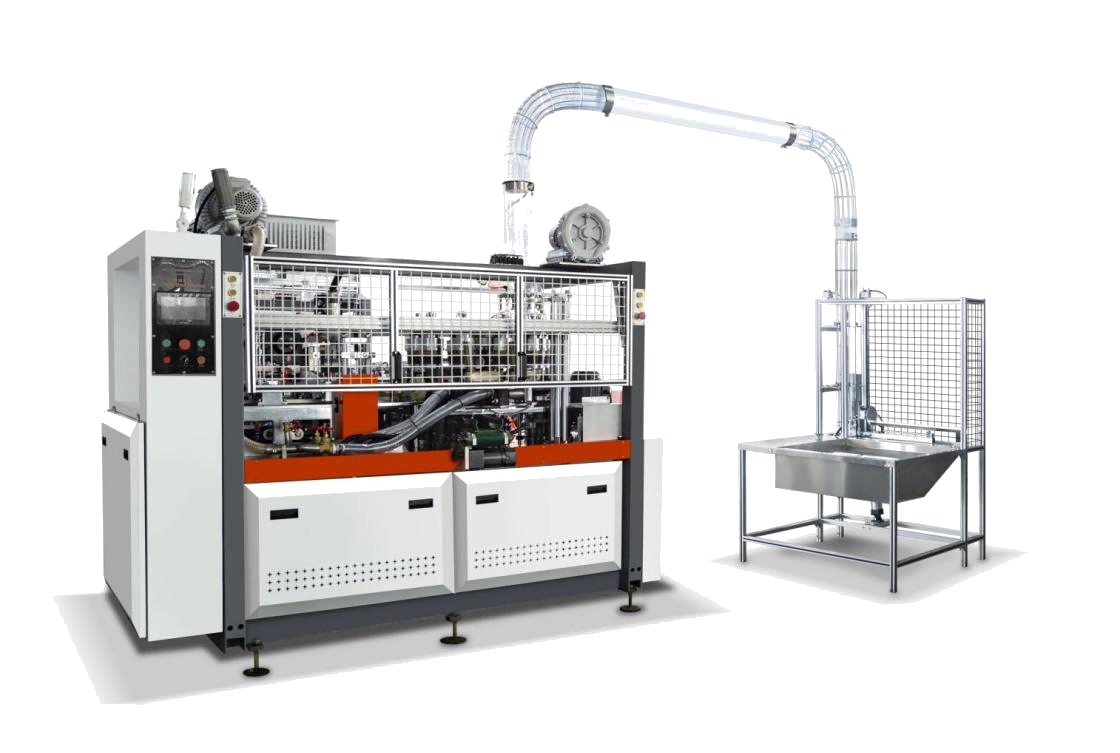

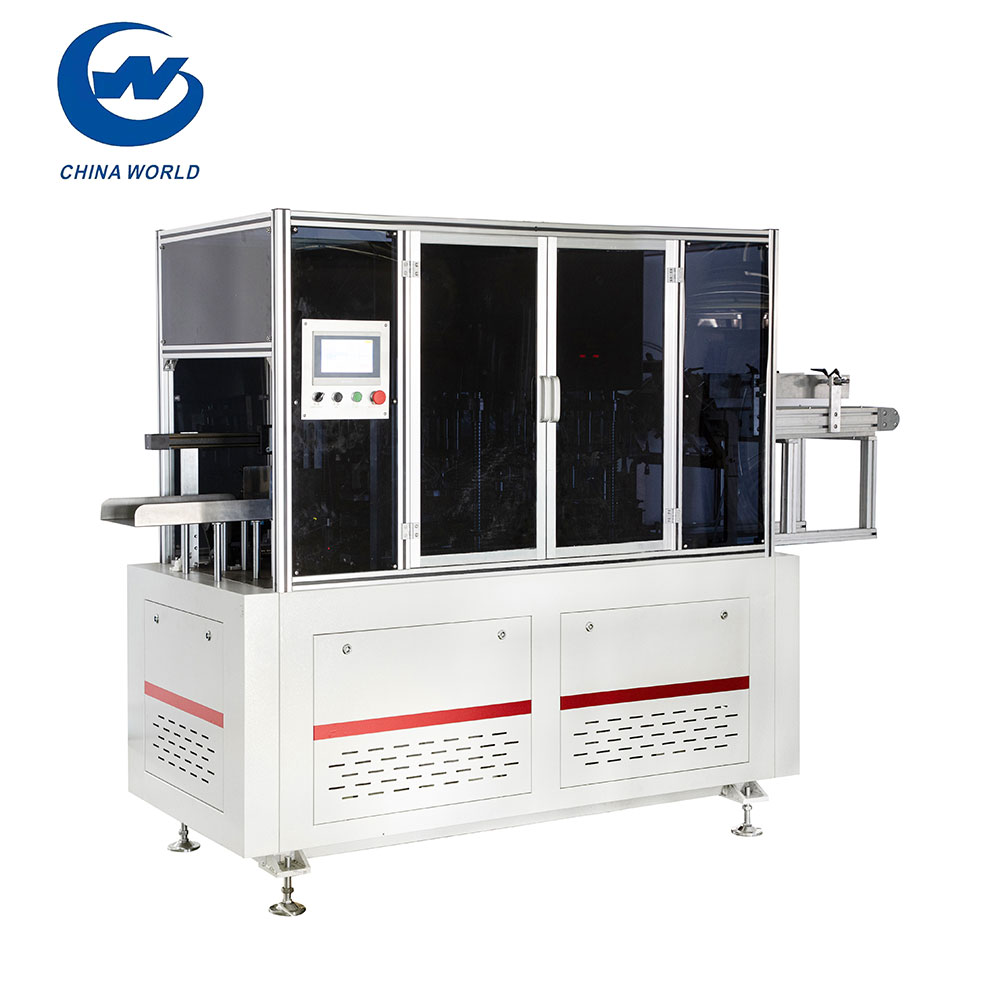

CW-JD260 High Speed V bottom paper bag machine

Performance and use:

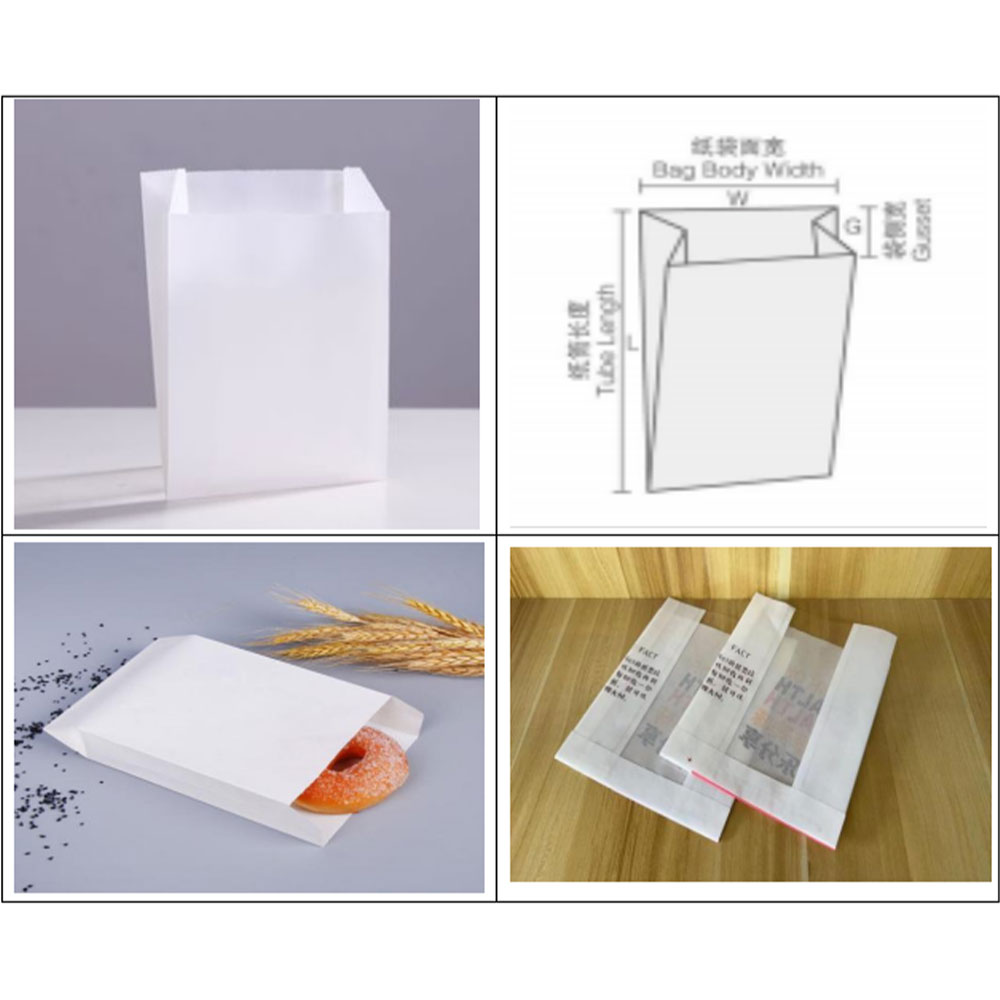

Automatic high-speed paper bag machine by the drum original color paper or printed drum paper such as kraft paper, striped kraft paper, oily paper, food shower film paper, medical paper and other paper roll material bag making process by thorn hole, glue, above, edge formation, interruption, bottom, paste bottom, finished bag output completed.This machine operation is more convenient, more efficient and more stable, is the ideal equipment for the production of various different paper bags, leisure food bags, bread bags, dried fruit bags and other environmentally friendly paper bags.

Main feature:

1 .Easy touch screen human-machine interface, the operation function is clear at a glance, easy to control

2 .The original Japanese Mitsubishi sports controller is adopted to ensure the stable high-speed operation through the integration with the optical fiber

3 .Japan Mitsubishi servo motor with German Schke color standard eye correction to accurately track the print bag size

4. Hydrhydraulic lifting structure and automatic constant tension control.

5. Brushless servo motor is used for raw material correction to reduce the alignment adjustment time of paper roll.

Technical parameters:

| Model | CW-JD260 |

| Cutting Length | 120-400mm |

| Bag length (L) | 100-380mm |

| Bag width(W) | 80-250mm |

| Insert size(G) | 20-110mm |

| Ladder height | 15-18mm |

| Paper bag speed | 100-600pcs/min |

| Paper width | 160-780mm |

| Maximum diameter of paper material | 1000mm |

| Inner diameter of paper | 76mm |

| Paper thickness | 45-80g/㎡ |

| Working gas | ≧0.12m³/min,0.5-0.8mpa |

| Power | 380v 3phase 4line 12kw |

| Total weight | 3500kg |

| outline | 6000*1600*1800mm |

Product Details Customization:Available Warranty:1 Year Applicable Objects:Beverage

Remarks: 1) Price Term: FOB NINGBO 2) Payment: T/T (30% for deposit, 70% before delivery) 3) Load time: 30 working days at sight the deposit. 4) After sale service: Spare parts guarantee for one year in machine arrival.

Remarks: 1) Price Term: FOB NINGBO 2) Payment: T/T (30% for deposit, 70% before delivery) 3) Load time: 30 working days at sight the deposit. 4) After sale service: Spare parts guarantee for one year in machine arrival.

1) Price Term: FOB NINGBO 2) Payment: T/T (30% for deposit, 70% before delivery) 3) Load time: 30 working days at sight the deposit. 4) After sale service: Spare parts guarantee for one year in machine arrival.

Remarks: 1) Price Term: FOB NINGBO 2) Payment: T/T (30% for deposit, 70% before delivery) 3) Load time: 30 working days at sight the deposit. 4) After sale service: Spare parts guarantee for one year in machine arrival.

1) Price Term: FOB NINGBO 2) Payment: T/T (30% for deposit, 70% before delivery) 3) Load time: 30 working days at sight the deposit. 4) After sale service: Spare parts guarantee for one year in machine arrival.

Carton forming machine is an ideal equipment for the production of carton boxes, such as hamburgers, french fries boxes, fried chicken boxes, children's lunch boxes, take-out boxes, triangular pizza boxes, etc. The structure is sturdy, good quality, low noise, and high efficiency. It has a paper feeding unit, an adjustment unit, a water unit, a forming unit, a finished product collection unit and a counting unit