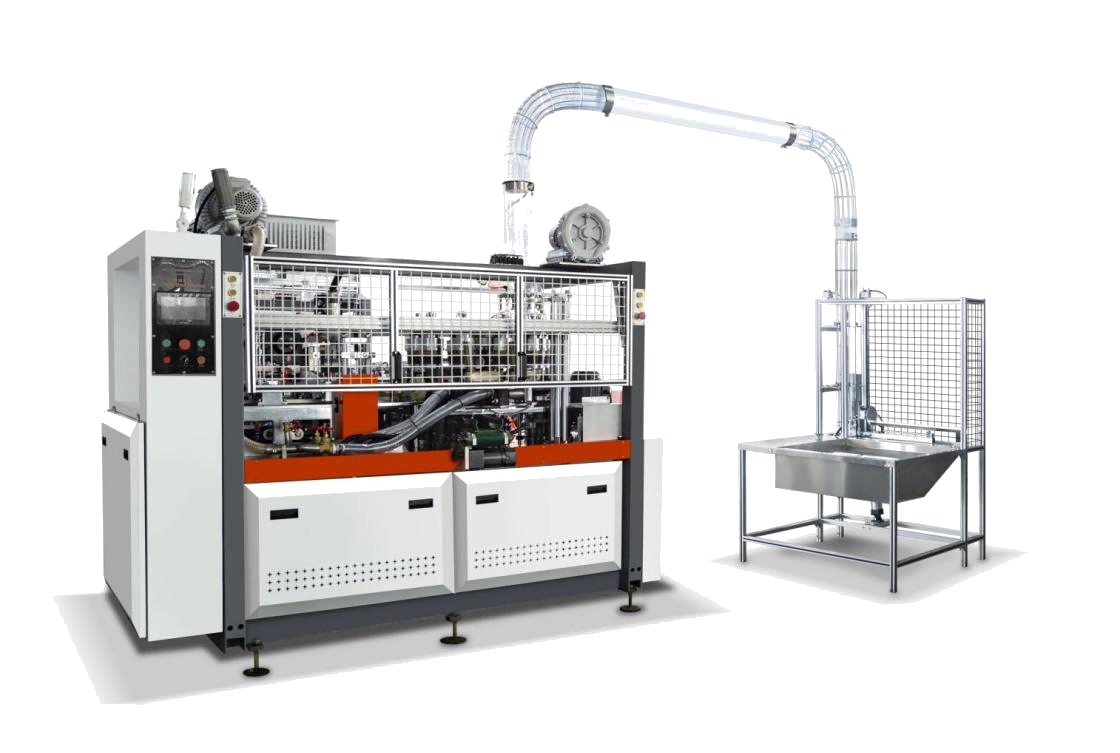

Principle of paper bowl machine equipment

A paper bowl making machine is a specialized piece of equipment designed to automatically produce disposable paper bowls commonly used for serving noodles, soups, desserts, and snacks. Similar to paper cup machines, it integrates mechanical forming, heating, and automation technologies to transform flat paper sheets into sturdy, leak-proof bowls. Understanding its working principle helps explain how everyday paper bowls are efficiently produced for the food service industry.

1. Overview and Raw Materials

The main raw material used in paper bowl production is PE-coated paper (polyethylene-coated paper). This paper has a thin plastic layer on one or both sides, making it waterproof and suitable for containing both hot and cold foods. The paper is usually pre-printed and cut into fan-shaped blanks, which are the starting materials for forming the bowl’s body. In addition, bottom roll paper is used to make the circular base of the bowl. Some machines also use double PE-coated paper to ensure better resistance against moisture and oil.

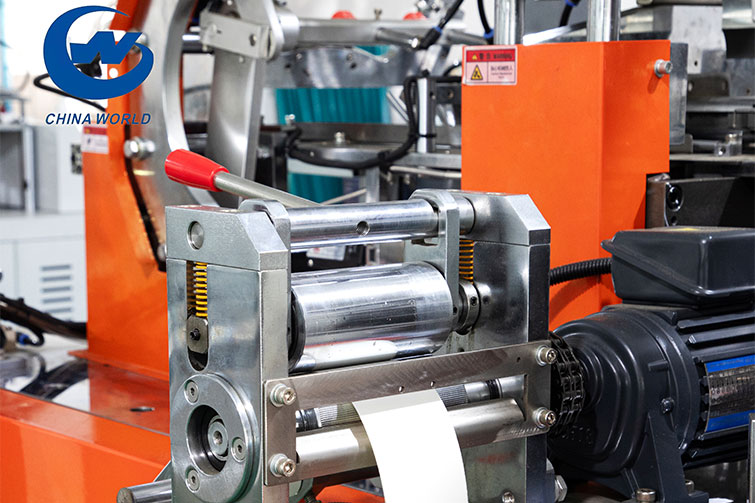

2. Feeding and Pre-Forming

The process begins with the automatic paper feeding system, which delivers pre-cut blanks into the machine. A mechanical arm or suction device picks up each blank and transfers it into the forming mold. Inside the mold, the paper is wrapped into a cylindrical or conical shape, depending on the bowl’s design. The overlapping edge of the paper blank is heated and pressed together. The hot air heater or ultrasonic sealing system melts the PE coating along the seam, bonding the edges tightly to form the bowl wall.

3. Bottom Formation and Sealing

After the body is shaped, the machine cuts round disks from the bottom roll paper. Each disk is accurately positioned and inserted into the lower part of the paper cylinder. The bowl’s bottom edge and side wall are then sealed together using high-temperature air or ultrasonic vibration. This step ensures a strong, leak-proof joint between the bottom and the wall. Precise heating control is crucial here — too much heat may damage the paper, while too little may cause poor bonding and leakage.

4. Expanding and Shaping

Unlike paper cups, paper bowls have a wider mouth and larger volume, which requires additional shaping. Once the bottom is sealed, the machine performs an expanding operation — a mechanical press stretches and widens the upper part of the bowl to achieve the desired diameter and curvature. The bowl takes its final three-dimensional shape during this stage, and the interior surface becomes smooth and even. Some machines use air pressure to assist in expansion for more uniform results.

5. Rim Curling and Edge Finishing

After shaping, the machine curls the upper edge of the bowl to create a smooth, rounded rim. This rim not only improves the bowl’s strength and user comfort but also enhances its visual appearance. The curling process involves heating and rotating molds that roll the edge outward while applying moderate pressure. The result is a clean, strong edge that prevents deformation and ensures compatibility with plastic lids if required.

6. Cooling, Ejection, and Stacking

Once the bowl is fully formed, it enters the cooling section, where ambient air or fans reduce its temperature to stabilize its shape. The formed bowls are then automatically ejected from the mold by a mechanical pusher. A counting and stacking system arranges the finished bowls into neat piles for easy packaging. High-end machines feature automatic detection systems that identify and reject defective bowls to maintain quality consistency.

7. Automation and Control System

Modern paper bowl machines use PLC (Programmable Logic Controller) systems combined with sensors and stepper or servo motors to achieve precise synchronization. The PLC monitors key parameters such as temperature, feeding speed, sealing time, and forming pressure. In the event of paper misfeeds, overheating, or mechanical failure, the control system can automatically stop the operation to prevent waste or damage. Touchscreen interfaces allow operators to adjust settings quickly and monitor production status in real time.

8. Energy Efficiency and Eco-Friendliness

To meet environmental standards, manufacturers are developing machines compatible with PLA-coated (biodegradable) paper materials instead of traditional PE-coated ones. These machines optimize heating systems and minimize paper waste to reduce energy consumption. Some also integrate waste paper collection and recycling mechanisms to enhance sustainability.

Conclusion

In summary, a paper bowl making machine transforms flat, coated paper into durable and hygienic disposable bowls through a sequence of precise operations: feeding, shaping, sealing, expanding, curling, and stacking. Its working principle relies on controlled heat and mechanical pressure to bond materials and form consistent shapes. With advanced automation and intelligent control, modern paper bowl machines achieve high speed, accuracy, and reliability, enabling mass production for global food packaging needs. As eco-friendly materials and energy-efficient designs continue to evolve, paper bowl machines will play an increasingly important role in promoting sustainable, disposable tableware solutions.