The working principle and process of a printing machine

A printing machine is a complex piece of equipment designed to transfer text and images onto various materials such as paper, cardboard, plastic, or fabric. It plays a crucial role in industries like publishing, packaging, and advertising. Although printing technology has evolved from manual presses to high-speed digital printers, the core principle remains the same: transferring ink from a printing plate or digital source onto a surface with precision and consistency. Understanding the working principle and process of a printing machine reveals how everyday products like books, newspapers, and labels are produced.

1. Basic Working Principle

The fundamental principle of a printing machine is ink transfer through pressure or digital projection. Depending on the type of machine, printing can be mechanical (as in offset, flexographic, or gravure printing) or digital (as in inkjet or laser printing).

In mechanical printing, the process begins with a printing plate that carries the image or text. The plate is coated with ink, and pressure is applied to transfer the inked image onto a blank substrate (such as paper). In digital printing, there is no plate; instead, digital data drives inkjet nozzles or laser beams to form the image directly on the surface.

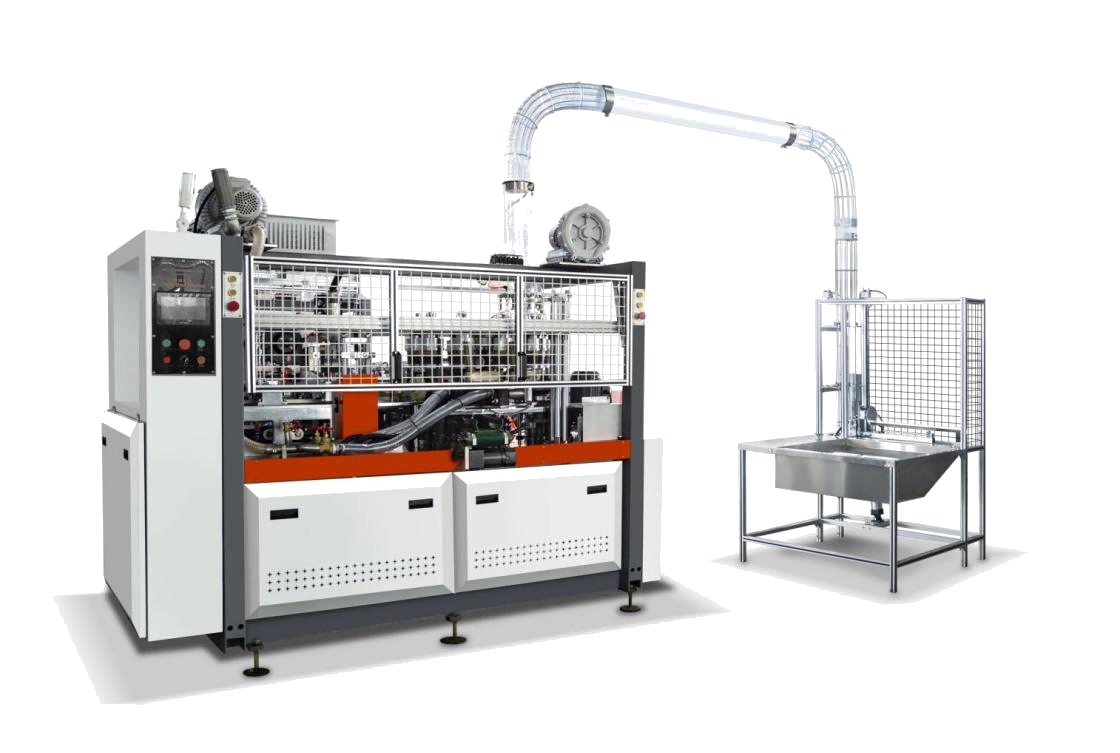

2. Major Components of a Printing Machine

A typical printing machine consists of several key parts:

- Feeding unit – automatically supplies paper or other materials into the machine.

- Printing unit – includes the plate cylinder, blanket cylinder, and impression cylinder (for offset printing), or inkjet heads (for digital printing).

- Ink system – stores, mixes, and delivers ink to the image areas of the plate.

- Dampening system – in offset printing, keeps non-image areas of the plate free of ink using a water-based solution.

- Drying unit – uses heat, UV light, or air to dry the ink on the printed material.

- Delivery system – stacks or rolls the printed sheets for collection and further processing.

3. The Printing Process

The general printing process follows several key steps, though details vary by printing type.

(1) Image Preparation

In traditional methods like offset printing, the first step is to create a printing plate. The plate is made using a photosensitive process where the design or text is transferred from a digital file onto a metal or polymer plate. In digital printing, this step is replaced by raster image processing (RIP), where the computer converts digital artwork into data that controls inkjet or laser components.

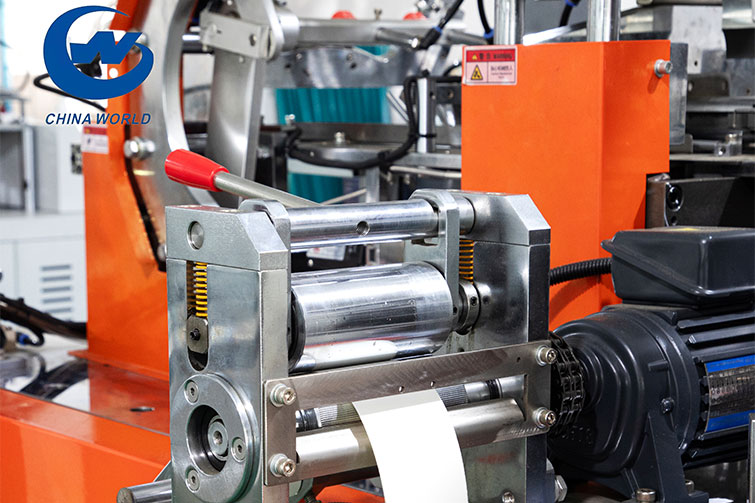

(2) Ink Application and Transfer

Once the plate is ready, it is mounted on the machine’s plate cylinder. The inking system applies ink to the image areas while a dampening system keeps the non-image areas clean. In offset printing, the image is first transferred from the plate to a rubber blanket cylinder, and then from the blanket to the paper — hence the name “offset.” This indirect method ensures better quality and extends the life of the printing plate.

In flexographic printing, flexible rubber plates and quick-drying inks are used, ideal for packaging materials like plastic films. Gravure printing, on the other hand, uses engraved cylinders filled with ink, perfect for long-run, high-quality image production such as magazines or wallpaper.

(3) Paper Feeding and Alignment

The feeding system ensures that each sheet or roll of paper is aligned perfectly before printing. Sensors and guides maintain consistent registration so that all colors and images line up accurately, especially in multi-color printing.

(4) Ink Drying and Fixing

After the image is transferred, the ink must dry quickly to avoid smudging. Depending on the ink type, different drying systems are used: hot air, infrared heating, or UV curing. In digital printing, inkjet printers use thermal or piezoelectric technology to control droplet placement and achieve instant drying.

(5) Output and Finishing

Finally, the printed materials are collected, stacked, or rolled for further finishing processes like cutting, folding, binding, or laminating. Some advanced printing machines integrate these steps automatically, increasing speed and efficiency.

4. Automation and Quality Control

Modern printing machines are equipped with computerized control systems that monitor ink density, color balance, registration, and printing pressure in real time. Automated sensors and cameras detect errors immediately, ensuring high-quality results and reducing waste. Digital printers go a step further, allowing variable data printing — producing personalized prints where each copy can contain different information, such as addresses or serial numbers.

5. Conclusion

The working principle of a printing machine combines science, engineering, and art. Whether mechanical or digital, the essence of printing is the controlled transfer of ink onto a surface to reproduce clear, consistent images and text. From the careful feeding of paper and precise ink application to the drying and finishing stages, every step is designed for accuracy and efficiency. As technology continues to evolve, printing machines are becoming faster, smarter, and more environmentally friendly, supporting the world’s constant demand for printed communication and packaging materials.